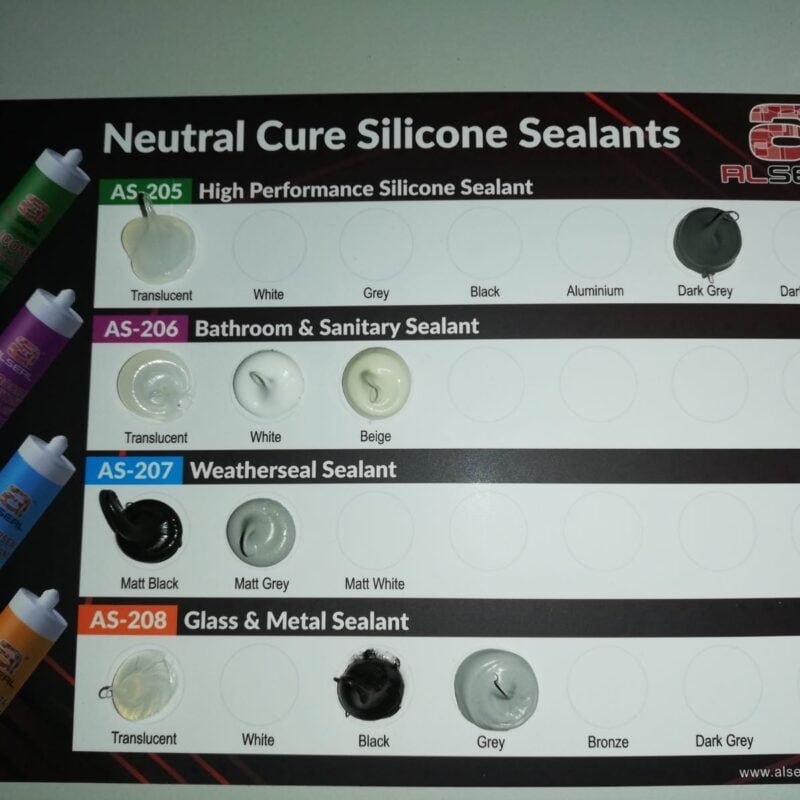

Weatherseal Silicone Sealant AS-207

From $8.00

Weatherseal Sealant well-suited for a strong weatherproof seal on most common building materials such as aluminium, galvanized and zinc-coated steel, painted surfaces, glass, brick and concrete. Widely used to seal external aluminium composite panels.

Description

ALSEAL Weatherseal Silicone Sealant AS-207 is a one-component, non-slumping high performance, 100% neutral cure silicone sealant formulated with a calcium carbonate filler system. It gives superior adhesion and durability in a wide range of glazing, weather sealing, and trade applications. It has excellent resistance to weathering, UV radiation, vibration, moisture, ozone, temperature extremes, airborne pollutants, and many cleaning detergents and solvents.

Applications

Weatherseal Silicone Sealant AS-207 is well-suited for a strong weatherproof seal on most common building materials such as aluminum, galvanized and zinc-coated steel, painted surfaces, glass, brick, and concrete. Widely used to seal external aluminum composite panels.

Features

- 100% neutral silicone

- ASTM C920 (Class 50) compliant

- Weatherproof seal

- Permanently flexible

- Indoor and outdoor use

- Matte finish

Joint design

- The specified sealant bead size should be calculated to comply with the compression and extension capabilities of the sealant in relation to the anticipated joint width due to expansion and contraction.

- Generally, calculation of the width sealant bead should be computed on the basis of a maximum ±50 % movement capability

- Minimum joint depth should not be less than 6 mm to accommodate movement.

- Silicone Sealant design joint width-to-depth ratio should be 2:1.

Usage instruction

1. Surfaces must be clean, dry, and free of dirt, grease, oil, or water.

2. Surfaces should be cleaned with alcohol, M.E.K., or other suitable solvents. Do not use soap or detergent.

3. For a neat finish, apply masking tape and remove it before sealant skins over.

4. Cut the nozzle at a 45° angle to the desired bead width and apply it to a substrate with a sealant application gun.

5. Tool the sealant within 10 minutes of extrusion before it skins. Tack-free in 20 minutes.

6. Uncured sealant can be cleaned up with mineral spirits.

Clean up

- Wet sealants can be cleaned up with acetone or mineral spirits.

- Cured sealants can only be removed mechanically.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Package | 24 pcs cartridges box, Cartridge |

| Color |