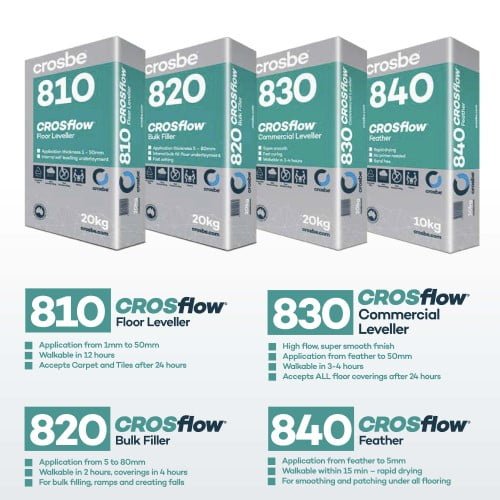

Self-leveling compound 810

$32.50

Self-leveling compound Crosbe Crosflow 810

Advanced technology, free form Silica leveler

Description

Self-leveling compound 810 CROSflow® 810 Floor Leveler is a self-leveling cementitious substrate with exceptional flow and adhesion properties. The CROSflow® 810 from Crosbe is suitable for interiors where thicknesses from 1 mm to 50 mm are required.

Use CROSflow® 810 floor leveler on new or old concrete substrates before applying floor covering. This product will take carpets and tiles after 24 hours and all other floorings after 72 hours.

Features:

• Suitable for indoor use.

• Residential and commercial use

• New construction

• Renovation of old floors

• Underlay for carpets, carpet tiles, and ceramic tiles after 24 hours of curing – refer to temperature considerations

• Substrate for vinyl and wood after 72 hours of cure – see temperature considerations

Advantages:

• Can be applied up to 50 mm in one layer.

• Tear and rain-resistant plastic bags that can be recycled to reduce product loss due to damaged packaging.

• High accuracy and constant weight of packages.

• Excellent adhesion.

• Exceptional fluidity and workability.

• Accessible traffic after 12 hours.

Surface preparation:

Concrete floors must be sound, clean, and dry. The surface should be free of dust, dirt, wax, grease, asphalt, latex and gypsum compounds, adhesives, paints, hardeners and sealants, and other contaminants that can act as destructive bonds. The concrete should be free of laitance, efflorescence, and hydrostatic pressure. Prepare the floor mechanically using recommended preparation methods such as shot blasting, loosening, diamond grinding, or other suitable methods to obtain a rough, clean, hard, hard, and open porous surface. Acid pickling is not a suitable method for preparing subfloors. Remove all dust and debris from the floor by vacuuming the surface with a suitable industrial grade H cleaner – must be equipped with a Hepa filter.

All concrete substrates must be fully cured and dry in accordance with AS 1884 (relative humidity less than 75% when measured in accordance with ASTM F2170). The temperature of the environment, surfaces, and materials must be above 10 ° C and below 35 ° C. For floors with a high moisture content or object Apply Moisture Vapor Barrier to increase moisture.

Primer:

Using a soft brush or broom, prime the prepared concrete surface with CROSflow® Primer and allow the primer to dry. The second coat of primer may be required in areas with very porous surfaces where the original coat has been completely absorbed. Allow the primer to dry completely to a clean thin film before applying CROSflow® 810 (approx. 1-2 hours depending on ambient conditions). Low temperatures can slow down the drying time of the primer. Do not apply self-leveling compound until the primer is completely dry.

Mixing:

Pour the recommended 4.2 – 4.6 liters of potable water into a clean mixing container and whilst mixing, slowly add the entire 20kg Self-leveling compound 810. Mixing should take place using a forced action high shear mixing paddle, with a mixer capable of stirring at 600rpm. Mix for approximately 2 – 3 minutes to a lump-free consistency.

NOTE!

Use the mix within 15 minutes after mixing, be sure to only mix a quantity that can be used within this time.

• Do NOT overwater the CROSflow® 810, use only the recommended mix water volume.

• Do NOT use a concrete or masonry mixer to mix CROSflow® 810.

• Do NOT mix by hand.

• Do NOT attempt to retemper mixed product once the working time of 30 minutes has been exceeded.

Coverage:

20kg bag of CROSflow® 810 will cover approximately 2.5m2 at 5mm thickness, 4.1m2 at 3mm thickness

Additional information

| Weight | 20 kg |

|---|---|

| Dimensions | 60 × 40 × 15 cm |

| Package | Bag |

CROSflow® 810 – Product Data:

| Property | Test Result |

| Working Time at 23°C | 30 minutes |

| Fresh Mix Density (Kg/m3) | 2013 |

| Yield (L/20Kg bag) | 12.0L @ 4.2L water addition 12.2L @ 4.6L water addition |

| 20 Kg Bags per cubic metre | 83 @ 4.2L water addition 82 @ 4.6L water addition |

| Foot Traffic at 23°C | Approx. 12 hours |

| Floor Coverings at 23°C | Carpet & Ceramic Tiles: 24 hours |

| Timber & Vinyl: 72 hours | |

| Setting Times at 23°C | Initial: 1 – 1.5 hours |

| Final: 1.5 – 2.0 hours | |

|

Compressive Strength |

1 Day: 8 – 9 MPa |

| 7 Day: 18 – 19 MPa | |

| 28 Days: 33 – 34 MPa | |

| Application Thickness | Minimum: Feather edge |

| Maximum: 50mm |